The materials we use

We make products so that you can be best prepared. Steel is where we started but innovation is at our core, meaning that we are constantly searching for materials with new functionality that will meet the needs of our customers better. Here’s an overview of some of our materials, from the classic to the innovative/modern.

Stainless Steel

Stainless Steel is not just part of our name (“inox”) but it’s also the backbone of our business and we’ve used it from knives to tools to watches to perfume bottles.

We source stainless steel from all over Europe and have been working with certain suppliers for almost 100 years, meaning that we can count on receiving the best quality from a source we trust.

We use Martensitic stainless steel because it can be hardened, which is a must to create strong blades and tools.

What’s not used directly in our production is never wasted – we collect the remaining steel and convert the grinding powder into pellets, send it back to our suppliers where it is turned back into steel.

To learn more, see our sustainability approach.

Damast Steel

With its distinctive waved pattern, Damast (also known as Damascus) is eye-catching, elegant yet with extraordinary strength.

Our Limited Edition Swiss Army Knives™ are amongst our most highly sought-after products. The origins of Damast steel are thought to come from Asia many centuries ago.

Today there are several methods of production to choose from including the classic method and powder metallurgy.

Our Damast is created using the powder metallurgy method, because it employs a very high quality of steel and a high degree of precision. Damast made using this method is also cleaner and has a very small amount of inclusions and impurities.

Sign up here to be informed when our next Damast Limited Edition knife is released.

Wood

The smooth and pleasing feel of wood in the hand has few comparisons, giving a warmth and haptic that even the most innovative materials can’t compete with.

We love to use wood for our Swiss Army Knife™ scales and our kitchen knives because it means that no two knives are alike.

Since sustainability is so important to us, we make sure to source all our wood from certified suppliers and all is European-sourced to reduce transportation emissions.

The wood handles we create for our kitchen are made of modified wood (maple and walnut) but still contain lignins and tannins which help to fight bacteria. But please bear in mind – we don’t recommend putting your wooden knives in the dishwasher.

See here for more tips on how to maintain your kitchen knives properly.

Alox

Alox is another iconic Victorinox material that we’ve been using since 1957 with the introduction of the first Pioneer knife. It also featured on the Soldier’s Knife which was redesigned in 1961 and used until 2008.

This name stands for the protective layer on the aluminum base material. It’s achieved cult status thanks to its unique pattern and haptics which make it easier to grip, while being lightweight and especially robust, thanks to the hardened oxide layer which helps to protect against damage and corrosion.

During production, the scales are punched from aluminum and then embossed, before going through a process called Eloxal which uses anodic oxidation to create a protective layer. Our annual Alox Limited Edition features a new color every year.

Click here to see more of our Limited Editions.

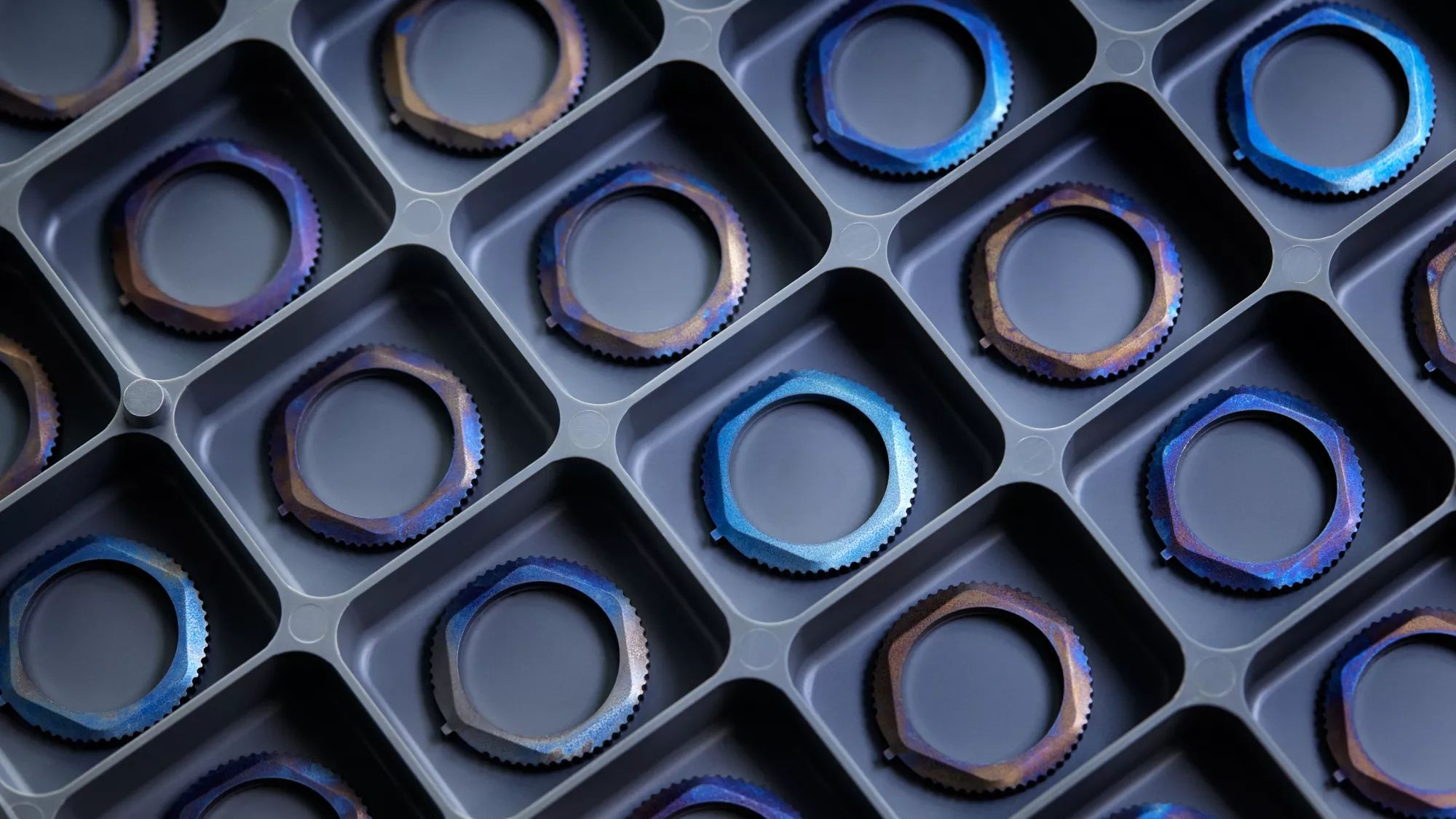

Watch Materials

We pay extraordinary attention to the materials that go into our watchmaking in Delémont.

As steel experts, we choose to work with austenitic stainless steel AISI 316L because this steel is anti-magnetic, has a very high corrosion resistance, is hypoallergenic and REACH compliant.

We also work with titanium (ASTM TI-Grade 2 and 5), which is known for its light weight and exceptional strength. It’s also biocompatible and exceptionally hypoallergenic.

We’re proud that our watches exceed what the law requires for the Swiss Made label, so sourcing Swiss materials is important to us – both our carbon watch cases and components, as well as the Super-Luminova ® which makes our dials and hands glow in the dark are sourced right here in Switzerland.

Travel Gear Materials

Our sustainability approach again comes to the fore with our travel gear.

We use SORPLAS™ which is a high-performance recycled polycarbonate developed and provided by Sony Semiconductor Solutions Corporation.

This recycled polycarbonate offers excellent durability and is used in up to 65% of the shell materials from our Spectra 3.0 Collection, with the rest being virgin polycarbonate.

We also use the cutting-edge SILVADUR™ antimicrobial lining in many of our Travel Gear collections, because it uses technology to inhibit the growth of microorganisms and can be cleaned up to 40 times without diminishing the effect of the treatment.

Fragrances

Wherever possible, Victorinox formulates new fragrances from natural-origin ingredients. Because there are some ingredients, such as woods, flowers or plants, that would need to be harvested from nature, Victorinox sometimes replaces the natural ingredients with upcycled ingredients or scent reconstitutions, as this leaves the nature intact and is therefore the more sustainable approach.

It goes without saying that Victorinox stands against animal testing therefore all fragrances qualify as cruelty free and Victorinox ensures that all new products only contain 100% vegan perfume oil. Looking ahead, Victorinox is working on reducing the allergens commonly used in fragrance production to underline our clear commitment towards clean fragrances.

About Victorinox

Official Website

All available products and the best browsing experience in one place

Stay up to date

Stories and offers, regularly in your mailbox.